ULTIMHEAT Technology Flat Heaters : Silicone Band Drum Heaters

ULTIMHEAT silicone heating elements are made of laminated silicone rubber sheets, vulcanized together through heat and high pressure on both sides of an embedded wire wound heating element. Fiberglass-reinforced silicone rubber gives heater dimensional stability without sacrificing flexibility. Silicone is used because of its high temperature resistance permanent temperature up to 200°C 390°F, high thermal conductivity ~7 10-4 W/cm.K and good electrical insulation properties ~12KV/mm A fiberglass grid, which is visible under the surface, reinforces the silicone rubber sheets. The wire wound heating element web covers the entire surface of the heater. This web could be designed such that holes and cut-outs are incorporated on the heater. This construction makes silicone rubber heaters an ideal solution to the requirements of many low and medium temperature applications, which do not conform to the shapes, sizes and dimensions of band, strip, cartridge, tubular and coil heaters.

Other general particularities of these heaters are:

- Not affected by vibration or flexing,

- Precise heating and lightweight

- Comply to UL94-VO (flame retardant) and ROHS

- Low Smoke and Low Toxicity

- Silicone is non-toxic, and moisture and chemical resistant

The band style drum heater is an easy way to heat up drum contents and can be used on plastic or

metal drums. One or more band heater can be used on the same drum. Silicone rubber drum heaters

keep products at temperatures or consistencies for handling in process. Their uniform heating

prevents scorching or degradation of the contents. Typical examples are:

- Consistency control of paints, oils, greases, fats, molasses, adhesives, plastics, mastics,

resins, syrups

- Freeze protection

- Maintaining liquid temperatures at 45-65°C (115-150 °F) in food industry water purification

systems

- Maintaining viscosity of chemical binder in sand casting mold operation

- Maintain polyester resin at 20-25°C (70-80 °F) for spray and pour equipment

Location on the drum: The silicone rubber band heater must be placed below the level of the fluid.

Fixing: By a spring lock-up that allows adjusting the band to the drum diameter, change position to the right place when content levels fluctuate, and also press the band on the drum surface, providing good thermal contact.

Length (dimension on drawing): designed to be used on main containers diameters. Consult factory if a special diameter is requested.

Width (dimension on drawing): in standard 100mm (4") , 200 mm ( 8"), 300mm (12") , 400 mm (16"), other on special order

Silicone foil minimum bending radius: 0.125" (3.2 mm)

Ingress protection: IP51

Maximum operating temperature on the silicone band: Warning: When improperly used or installed, the silicone band heater surface temperature can reach 230 °C (446 °F)

This maximum temperature should never been reached in normal use, when the band heater is correctly in contact with the drum and the temperature control thermostat adjusted to the right value.

Minimum ambient temperature: -10 °C (+15 °F),

Voltage: 115 or 230VAC

Resistance tolerance: -5%/+10% (tighter tolerances are achievable)

Power tolerance: -10% to + 5%

Heating Element: Silicone insulated spiral wound resistance element

Control: Temperature control is provided by mechanical thermostat with set point adjustment from +10°C to+110°C (+15~230°F), with a power supply on pilot light and power output pilot light . The thermostat knob has an internal adjustable stop that allows to limit the maximum or minimum set point

Control housing: IP51, 100 x 50 x 55 mm with PG13.5 cable gland output

Power Cable: 2 meters cable, 3 x 1mm². On request it can be supplied with UL or Euro plug cords

Health and Safety standards: The heaters have been designed in compliance withEECLow Voltage Directive (LVD) 2006/95/EC and EMC directive 2004/108/EC and CE marked accordingly.

They must be installed in accordance with all local applicable instructions, codes, and regulations.

Standard watt density:Quality control routine tests: Each element is 100% tested for continuity, resistance and insulation. Tests are made according to EN 60335-1 and EN 50106 standards

Dielectric Strength: 1500V AC, 2s, 0.5 mA (single insulation models) or the typical approval agency recommendation of 2 x input voltage +1000 volts.

Insulation resistance: More than 10 Mohms

Surface temperature: Temperature that the silicone rubber heater will attain when suspended in still air at 70 °F (20°C) depends of the watt density. Below 5.2 w/inch², (0.8 w/cm²), the temperature will rise during some minutes and stabilize at a temperature below the critical 500 °F (260°C) which is the highest technically acceptable surface temperature.

| Surface temperature after stabilization /watt density | |||||||||||||

| W/cm² | 0.05 | 0.10 | 0.15 | 0.20 | 0.30 | 0.40 | 0.45 | 0.50 | 0.60 | 0.70 | 0.8 | 0.9 | 1.0 |

| Stabilization Temperature °C | 40 | 70 | 90 | 105 | 135 | 165 | 175 | 190 | 210 | 230 | 250 | 260 | 270 |

| W/inch² | 0.32 | 0.64 | 0.97 | 1.3 | 1.9 | 2.6 | 2.9 | 3.2 | 3.9 | 4.8 | 5.2 | 5.8 | 6.5 |

| Stabilization Temperature °F | 104 | 158 | 194 | 221 | 275 | 329 | 320 | 347 | 410 | 446 | 482 | 500 | 518 |

- Power to the band heater must be disconnected when the container is empty

- Power to the band heater must be disconnected when the container is being filled

- Power to the band heater must be disconnected during installation or removal of the heater

itself.

- The band heater must be operated in a dry environment

- The container must be vented to avoid build up of internal pressure.

- These heaters are not suitable for outdoor use, and must be protected from rain, dust and

condensation.

- These heaters are not suitable for use in flammable or explosive areas

- Do not operate heater above safety rated temperature (This temperature depends of the heated liquid,

and must be checked before connecting the heater to any power supply)

- Use specified sized heater with same sized container

- Read installation instruction before use

Our experienced designers can assist in your design efforts to build a surface heater specifically for your application. In addition, we can look to optimize your current element designs and recommend proper watt densities, controls and element construction. We will conduct a thorough design review and present a proposal and quotation, followed by sample elements upon approval. We also provide testing services and gather agency approvals to verify and ensure that the element construction and design will be optimal for your application.

We protect your intellectual property in confidential fashion. Many of our large clients and ongoing projects are protected with NDA's.

The 100 mm width is a very popular item because it is the cheapest, but it does not perform the best, and provides heating power on only a very small percentage of the container surface. Overheating or slow heating on viscous liquids are common resulting problems. The solution is to provide the appropriate heating surface. Larger heating surface can be used to provide more power or/and reduce the heating surface watt density.

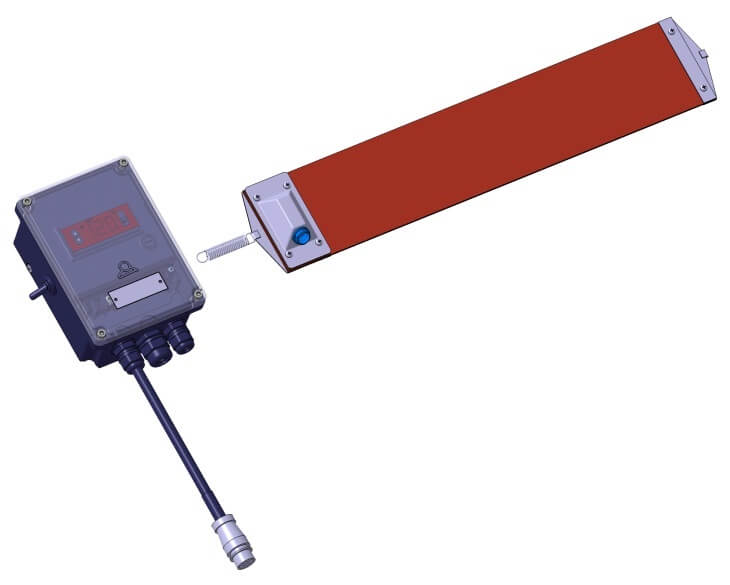

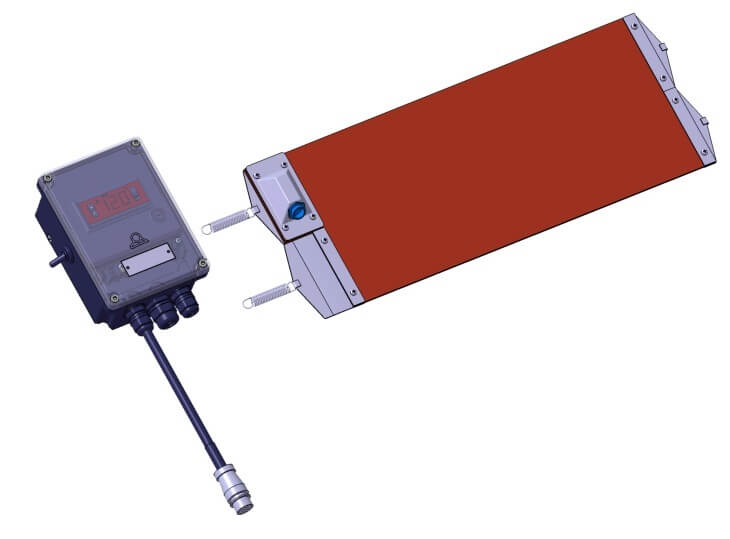

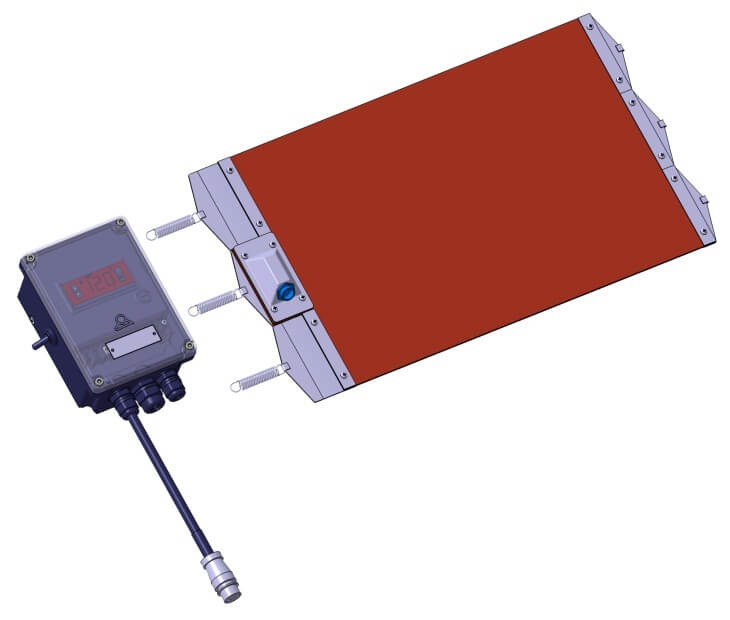

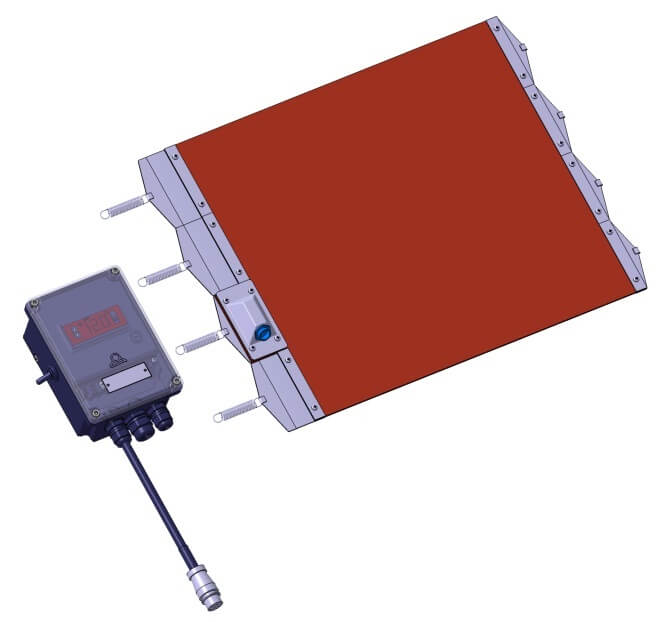

Ultimheat provides 4 different widths to cover all applications with satisfactory results both in metal or plastic containers. (Pictures show remote electronic control, but any other kind of control is possible)

100 mm: The most popular. We do not recommend to use surface watt power higher than 0.8 w/cm²

200 mm: Allows to twice the power or to divide by two the surface watt power. A good solution in both cases, and covers a lot of applications.

300 mm: Allows very low surface rating , but must be careful not to use it on drum ribs, the silicone belt must be in full contact with the drum surface. A good technical solution for plastic drums and plastic pails without ribs

400 mm: Allows extra low surface rating, but cannot be used on most metal drums, because the 400 mm width will cover the drum ribs. A good technical solution for industrial tanks heating when the silicone belt is in full contact with a ribless flat surface. Also a good technical solution for plastic drums and plastic pails without ribs.

(Width 100 mm, 10-110°C bulb and capillary thermostat, 2 meters cord without plug)

Click on reference to download PDF files

| References** | Description | w/cm² | Drum Dia mm +/-12 mm | Drum Dia (inch), +/- 0.5" | total length mm (A) | Length inches | Power Watts | V.AC |

| 9ABNA0H78140KB00 | 5-gallon (19 liter) plastic pail, | 0,2 | 290 | 11,4 | 871 | 34,3 | 140 | 220/230 |

| 9ABNA0H78560KB00 | 5-gallon (19 liter) metal pail, | 0,8 | 290 | 11,4 | 871 | 34,3 | 560 | 220/230 |

| 9ABNA0J18180KB00 | 15-gallon (57 liter) plastic drum | 0,2 | 356 | 14,0 | 1078 | 42,4 | 180 | 220/230 |

| 9ABNA0J18730KB00 | 15-gallon (57 liter) steel drum, | 0,8 | 356 | 14,0 | 1078 | 42,4 | 730 | 220/230 |

| 9ABNA0N08250KB00 | 30-gallon (114 liter) plastic drum | 0,2 | 460 | 18,1 | 1404 | 55,3 | 250 | 220/230 |

| 9ABNA0N08990KB00 | 30-gallon (114 liter) steel drum | 0,8 | 460 | 18,1 | 1404 | 55,3 | 990 | 220/230 |

| 9ABNA0Q58320KB00 | 55-gallon (208 liter) plastic drum | 0,2 | 570 | 22,4 | 1750 | 68,9 | 320 | 220/230 |

| 9ABNA0Q58A25KB00 | 55-gallon (208 liter) steel drum | 0,8 | 570 | 22,4 | 1750 | 68,9 | 1250 | 220/230 |

| 9ABNA0Q58A50KB00 | High power Heater for 55-gallon (208 liter) steel drum | 0,95 | 570 | 22,4 | 1750 | 68,9 | 1500 | 220/230 |

| 9ABNA0H75140KB00 | 5-gallon (19 liter) plastic pail, | 0,3 | 290 | 11,4 | 871 | 34,3 | 140 | 110 /115 |

| 9ABNA0H75560KB00 | 5-gallon (19 liter) metal pail, | 0,8 | 290 | 11,4 | 871 | 34,3 | 560 | 110 /115 |

| 9ABNA0J15180KB00 | 15-gallon (57 liter) plastic drum | 0,2 | 356 | 14,0 | 1078 | 42,4 | 180 | 110 /115 |

| 9ABNA0J18730KB00 | 15-gallon (57 liter) steel drum, | 0,8 | 356 | 14,0 | 1078 | 42,4 | 730 | 110 /115 |

| 9ABNA0N05250KB00 | 30-gallon (114 liter) plastic drum | 0,2 | 460 | 18,1 | 1404 | 55,3 | 250 | 110 /115 |

| 9ABNA0N05990KB00 | 30-gallon (114 liter) steel drum | 0,8 | 460 | 18,1 | 1404 | 55,3 | 990 | 110 /115 |

| 9ABNA0Q55320KB00 | 55-gallon (208 liter) plastic drum | 0,2 | 570 | 22,4 | 1750 | 68,9 | 320 | 110 /115 |

| 9ABNA0Q55A25KB00 | 55-gallon (208 liter) steel drum | 0,8 | 570 | 22,4 | 1750 | 68,9 | 1250 | 110 /115 |

| 9ABNA0Q55A50KB00 | High power heater for 55-gallon (208 liter) steel drum | 0,95 | 570 | 22,4 | 1750 | 68,9 | 1500 | 110 /115 |

Warning: These heating values have been optimized to apply maximum 0.2W/cm² on the plastic container heated surface and 0.8W/cm² on the steel containers surface. The reduced value of 0.2 W/cm² is also recommended for low temperature heating or low temperature resistant liquids.

The 0.95 W/cm² model must be carefully used as temperature it can reach if improperly installed is higher than silicone band temperature resistance.