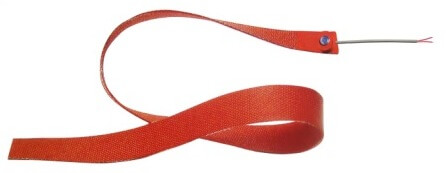

2 x 0.5 mm² (AWG20) Flat cable without plug

ULTIMHEAT Technology Flat Heaters : Anti freeze Band Heaters

ULTIMHEAT silicone heating elements are made of laminated silicone rubber sheets, vulcanized together through heat and high pressure on both sides of an embedded wire wound heating element. Fiberglass-reinforced silicone rubber gives heater dimensional stability without sacrificing flexibility. Silicone is used because of its high temperature resistance (permanent temperature up to 200°C (390°F), high thermal conductivity (~7 10-4 W/cm.K) and good electrical insulation properties (~12KV/mm)

A fiberglass grid, which is visible under the surface, reinforces the silicone rubber sheets. The wire wound heating element web covers the entire surface of the heater. This construction makes silicone rubber heaters an ideal solution to the requirements of many low and medium temperature applications with small sizes or complicated pattern. Their flat shape and small thickness make them highly appreciated for small diameter pipes, without need to modify the existing foam insulation.

Silicone flexible band deicing heaters are designed to provide freeze protection to metallic and plastic piping, valves, pumps, water meters and are usually wrapped around the equipments or fixed axially under the pipe insulation foam with cable ties or adhesive tape. We recommend 10 mm thickness insulation foam for pipes up to 24 mm and 20 mm for diameters over this size.

Length: 800 mm to 2000 mm,+/- 5 mm (32" to 80" +/- 3/16)

Width: 25 mm +/- 1.5 mm (1"+/- 1/16)

Standard heater thickness without adhesive, cable output and thermostat over-molding not

included: 1.60 mm +/- 0.15 mm (0.065 inch +/- 0.005") .\Add 0.1 mm (0.005") to above dimensions

for adhesive foil backing.

Maximum total thickness over cable output: 4.6 mm

Maximum total thickness over thermostat: 17 mm Silicone foil minimum bending radius: 0.125"

(3.2 mm)

Standard Weight: 0.24 gr/cm² 240 g/m² (8 oz./ft²) + cable and thermostat

Ingress protection: IP65

Maximum operating temperature*: the silicone foil can withstand peak 230 °C (446 °F),

continuous: 200 °C (390 °F), but these temperatures cannot be reached if these heaters are used on

water pipes and according to installation instructions

Minimum ambient temperature on the heater: -60 °C (-80 °F)*

*These maximum and minimum temperatures apply to silicone heaters only. Restriction apply for

controls and cables

Voltage: 12V to 240VAC

Resistance tolerance: -5%/+10% (tighter tolerances are achievable)

Power tolerance: -10% to + 5%

Watt density: The limitation factor is the heating foil and pipe maximum acceptable

temperature. This temperature is dependent upon three factors:

- Temperature exchange with ambient or surface

- The maximum operating temperature

- Heater temperature control

Standard watt density:

0.05 w/cm² (0.32 w/inch²).

-0.1 w/cm² (0.64 w/inch²). Warning: When used on plastic pipes or foam insulated pipes, do not use

higher than 0.1w/cm² (0.64 w/ inch²) watt density to avoid melting plastic pipes or pipe foam

insulation.

-0.2 w/cm² (1.3 w/inch²).

Built in thermostat: They are equipped with one ambient temperature thermostat, which will

start heating automatically when ambient temperature goes down to 5 °C +/- 3 °C. Thermostat sensing

surface must be outside insulation.

Quality control routine tests: Each element is 100% tested for continuity, resistance and

insulation. Tests are made according to EN 60335-1 and EN 50106 standards

Dielectric Strength: 1500V AC, 2s, 0.5 mA (single insulation models) or the typical approval

agency recommendation of 2 x input voltage +1000 volts.

Insulation resistance: More than 10 Mohms

Surface temperature: Temperature that the silicone rubber heater will attain when suspended in

still air at 70 °F (20°C) depends of the watt density.

|

Surface temperature after stabilization /watt density |

|||||||||||||

|

W/cm² |

0.05 |

0.10 |

0.15 |

0.20 |

0.30 |

0.40 |

0.45 |

0.50 |

0.60 |

0.70 |

0.8 |

0.9 |

1.0 |

|

Stabilization Temperature °C |

40 |

70 |

90 |

105 |

135 |

165 |

175 |

190 |

210 |

230 |

250 |

260 |

270 |

|

W/inch² |

0.32 |

0.64 |

0.97 |

1.3 |

1.9 |

2.6 |

2.9 |

3.2 |

3.9 |

4.8 |

5.2 |

5.8 |

6.5 |

|

Stabilization Temperature °F |

104 |

158 |

194 |

221 |

275 |

329 |

320 |

347 |

410 |

446 |

482 |

500 |

518 |

Electrical connection: HO3VVH2F – 2 x 0.5 mm² (equivalent to AWG 20), PVC insulated cable, maximum voltage 300V, flexible stranded plated copper wire, with or without over-molded plug. Length 1 meter. Temperature limits on the cable: -5+60°C.

2 x 0.5 mm² (AWG20) Flat cable without plug

2 x AWG 20 Flat cable with UL plug

HO3VVH2F – 2 x 0.5 mm² Flat cable with 2.5 A Euro plug

Standard flexible silicone deicing band Heaters : 5°C Ambient disc thermostat, 1m PVC insulated cable, horizontal output, 0.05 to 0.2 w/ cm² (0.32 to 1.3 w/inch² )

Rectangular heater main references, 0.05 w/cm² (0.32 w/inch2). (Click on reference to download drawing)

| Reference | Width mm | Width inches | Length mm | Length inches | Power Watts | Voltage | Cable Style |

| 9ADC25H08009FB00 | 25 | 1,0 | 800 | 31,5 | 9 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25J08012FB00 | 25 | 1,0 | 1000 | 39,4 | 12 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25O08018FB00 | 25 | 1,0 | 1500 | 59,1 | 18 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25T08024FB00 | 25 | 1,0 | 2000 | 78,7 | 24 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25J05012FT00 | 25 | 1,0 | 800 | 31,5 | 9 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

| 9ADC25J05012FT00 | 25 | 1,0 | 1000 | 39,4 | 12 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

| 9ADC25O05018FT00 | 25 | 1,0 | 1500 | 59,1 | 18 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

| 9ADC25T05024FT00 | 25 | 1,0 | 2000 | 78,7 | 24 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

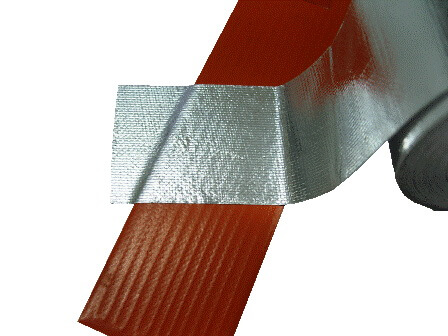

Reinforced high temperature aluminum adhesive tape

Reference: 96ALTA0550

Rectangular heater main references, 0.1 w/cm² (0.64 w/inch2). (Click on reference to download drawing)

| reference | Width mm | Width inches | Length mm | Length inches | Power Watts | voltage | Cabble Style |

| 9ADC25H08019FB00 | 25 | 1,0 | 800 | 31,5 | 19 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25J08024FB00 | 25 | 1,0 | 1000 | 39,4 | 24 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25O08036FB00 | 25 | 1,0 | 1500 | 59,1 | 36 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25T08049FB00 | 25 | 1,0 | 2000 | 78,7 | 49 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25H05019FT00 | 25 | 1,0 | 800 | 31,5 | 19 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

| 9ADC25J05024FT00 | 25 | 1,0 | 1000 | 39,4 | 24 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

| 9ADC25O05036FT00 | 25 | 1,0 | 1500 | 59,1 | 36 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

| 9ADC25T05049FT00 | 25 | 1,0 | 2000 | 78,7 | 49 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

Rectangular heater main references, 0.2 w/cm² (1.3 w/inch2) Warning: Not recommended on most of plastic pipes or surfaces (Click on reference to download drawing)

| reference | Width mm | Width inches | Length mm | Length inches | Power Watts | voltage | Cabble Style |

| 9ADC25H08038FB00 | 25 | 1,0 | 800 | 31,5 | 38 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25J08048FB00 | 25 | 1,0 | 1000 | 39,4 | 48 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25O08073FB00 | 25 | 1,0 | 1500 | 59,1 | 73 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25T08098FB00 | 25 | 1,0 | 2000 | 78,7 | 98 | 220/230 | 2 x 0,5 mm², H03-VVH2, no plug |

| 9ADC25H05038FT00 | 25 | 1,0 | 800 | 31,5 | 38 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

| 9ADC25J05048FT00 | 25 | 1,0 | 1000 | 39,4 | 48 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

| 9ADC25O05073FT00 | 25 | 1,0 | 1500 | 59,1 | 73 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

| 9ADC25T05098FT00 | 25 | 1,0 | 2000 | 78,7 | 98 | 110/115 | 2 x AWG20 cable, PVC insulated, style 2664, no plug |

Adhesive backside: replace the last character (0) by A

Warning:

- Silicone rubber heaters are not suitable for: radiation, vacuum, or prolonged exposure to

oil

- When these bands are used on thermally insulated pipes, they must be installed under the

insulation and always in contact with the pipe surface. We recommend fixing them on the

equipment with armed adhesive tape or cable ties

Design Services: Our experienced designers can assist in your design efforts to build a surface heater specifically for your application. In addition, we can look to optimize your current element designs and recommend proper watt densities, controls and element construction. We will conduct a thorough design review and present a proposal and quotation, followed by sample elements upon approval. We also provide testing services and gather agency approvals to verify and ensure that the element construction and design will be optimal for your application.

Custom designs Protection: We protect your intellectual property in confidential fashion. Many of our large clients and ongoing projects are protected with NDA's.