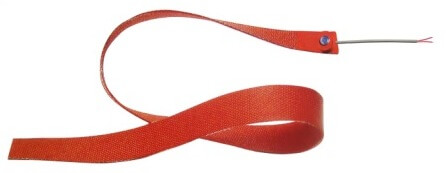

Horizontal wires terminals, FEP insulation (standard)

ULTIMHEAT Technology : Bands Heaters without Controls Type 9A

ULTIMHEAT silicone heating elements are made of laminated silicone rubber sheets, vulcanized together through heat and high pressure on both sides of an embedded wire wound heating element. Fiberglass-reinforced silicone rubber gives heater dimensional stability without sacrificing flexibility. Silicone is used because of its high temperature resistance (permanent temperature up to 200°C (390°F), high thermal conductivity (~7 10-4 W/cm.K) and good electrical insulation properties (~12KV/mm)

A fiberglass grid, which is visible under the surface, reinforces the silicone rubber sheets. The wire wound heating element web covers the entire surface of the heater. This web could be designed such that holes and cut-outs are incorporated on the heater. This construction makes silicone rubber heaters an ideal solution to the requirements of many low and medium temperature applications, which do not conform to the shapes, sizes and dimensions of band, strip, cartridge, tubular and coil heaters.

Silicone flexible band heaters are designed to provide process temperature maintenance to metallic and plastic piping, valves, pumps, water meters and are is usually wrapped around the equipment.

Length: 250 mm to 700 mm (10” to 30”). On special order: up to 1000mm (40”)

Width: 25, 50 and 75 mm (1”, 2”, 3” )

Dimensional tolerances:

If the element is temperature controlled sufficiently or the heat is taken away by forced air or a

heat sink, the Watt density can range up to 0.8w/cm², (5.2 w/inch²). More typical designs are equal or

below 0.4w/cm², (2.6 w/inch²)

Standard watt density:

-0.1 w/cm² (0.64 w/inch²). Warning: When used on plastic pipes or foam insulated pipes, do not use

higher than 0.1w/cm² (0.64 w/ inch²) watt density to avoid melting plastic pipes or pipe foam

insulation.

-0.2 w/cm² (1.3 w/inch²)

-0.4 w/cm² (2.6 w/inch²)

-0.8 w/cm² (5.2 w/inch²)

Quality control routine tests: Each element is 100% tested for continuity, resistance and

insulation. Tests are made according to EN 60335-1 and EN 50106 standards

Dielectric Strength: 1500V AC, 2s, 0.5 mA (single insulation models) or the typical approval

agency recommendation of 2 x input voltage +1000 volts.

Insulation resistance: More than 10 Mohms

Surface temperature: Temperature that the silicone rubber heater will attain when suspended in still air at 70 °F (20°C) depends of the watt density. Below 5.2 w/inch², (0.8 w/cm²), the temperature will rise during some minutes and stabilize at a temperature below the critical 500 °F (260°C) which is the highest technically acceptable surface temperature.

|

Surface temperature after stabilization /watt density |

|||||||||||||

|

W/cm² |

0.05 |

0.10 |

0.15 |

0.20 |

0.30 |

0.40 |

0.45 |

0.50 |

0.60 |

0.70 |

0.8 |

0.9 |

1.0 |

|

Stabilization Temperature °C |

40 |

70 |

90 |

105 |

135 |

165 |

175 |

190 |

210 |

230 |

250 |

260 |

270 |

|

W/inch² |

0.32 |

0.64 |

0.97 |

1.3 |

1.9 |

2.6 |

2.9 |

3.2 |

3.9 |

4.8 |

5.2 |

5.8 |

6.5 |

|

Stabilization Temperature °F |

104 |

158 |

194 |

221 |

275 |

329 |

320 |

347 |

410 |

446 |

482 |

500 |

518 |

Leads: Standard leads for heaters are FEP insulated, flexible stranded plated copper wire. They

are UL Style 1330 rated for 180°C/ 600 volt operation. Lead types and exit locations are adaptable to

application requirements. Standard length is 200 mm.

Standard wire gauges:

AWG22 (or 0.3 mm²) is standard for rating up 3.5A

AWG20 (or 0.5 mm²) is standard for rating from 3.6 to 5.5A

Electrical connection output: standard is wire leads horizontal output. On request we can provide

vertical leads output, side output with 6.3 x 0.8 tab terminals or flat cable. Wires can be equipped

with terminals on request. Built in connectors must be submitted to our engineering department for

feasibility

.jpg)

Horizontal wires terminals, FEP insulation (standard)

.jpg)

Horizontal Flat cable without plug

.jpg)

Horizontal Flat cable with UL plug

.jpg)

Horizontal Flat cable with Euro plug

On the heaters surface it can be over-molded disc thermostats, temperature sensors, fixed setting bimetal thermostats, thermal cutouts and surface mounting adjustable bimetal thermostat.

.jpg)

Thermocouple J

.jpg)

Pt 100

.jpg)

Thermal cut out (fuses at preset temperature)

.jpg)

Disc thermostat (ambient temperature sensing). The thermostat sensing surface must be outside insulation.

.jpg)

Disc thermostat, surface temperature sensing (manual or automatic reset)

.jpg)

High limit fixed setting bimetal strip thermostat (snap action, large differential)

Other Options:

- Adhesive backside for application on various surfaces such as glass, steel, plastic

Main references

Standard flexible silicone band Heaters :

No controls, 200 mm FEP insulated wires, horizontal output, 0.1 to 0.8 w/ cm²

(0.64 to 5.2 w/inch² )

|

Band heater, 0,1w/cm², no controls, 2 wires 200 mm FEP

insulated |

||||||||

|

reference |

Width mm |

Width inches |

Length mm |

Length inches |

Power Watts |

voltage |

amps |

wire size |

|

25 |

1,0 |

250 |

9,8 |

6,25 |

220/230 |

0,03 |

AWG22 |

|

|

25 |

1,0 |

300 |

11,8 |

7,5 |

220/230 |

0,03 |

AWG22 |

|

|

25 |

1,0 |

400 |

15,7 |

10 |

220/230 |

0,04 |

AWG22 |

|

|

25 |

1,0 |

500 |

19,7 |

12,5 |

220/230 |

0,05 |

AWG22 |

|

|

25 |

1,0 |

600 |

23,6 |

15 |

220/230 |

0,07 |

AWG22 |

|

|

25 |

1,0 |

700 |

27,6 |

17,5 |

220/230 |

0,08 |

AWG22 |

|

|

50 |

2,0 |

250 |

9,8 |

12,5 |

220/230 |

0,05 |

AWG22 |

|

|

50 |

2,0 |

300 |

11,8 |

15 |

220/230 |

0,07 |

AWG22 |

|

|

50 |

2,0 |

400 |

15,7 |

20 |

220/230 |

0,09 |

AWG22 |

|

|

50 |

2,0 |

500 |

19,7 |

25 |

220/230 |

0,11 |

AWG22 |

|

|

50 |

2,0 |

600 |

23,6 |

30 |

220/230 |

0,13 |

AWG22 |

|

|

50 |

2,0 |

700 |

27,6 |

35 |

220/230 |

0,2 |

AWG22 |

|

|

75 |

3,0 |

400 |

15,7 |

30 |

220/230 |

0,1 |

AWG22 |

|

|

75 |

3,0 |

500 |

19,7 |

37,5 |

220/230 |

0,2 |

AWG22 |

|

|

75 |

3,0 |

600 |

23,6 |

45 |

220/230 |

0,2 |

AWG22 |

|

|

75 |

3,0 |

700 |

27,6 |

52,5 |

220/230 |

0,2 |

AWG22 |

|

|

25 |

1,0 |

250 |

9,8 |

6,25 |

110/115 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

300 |

11,8 |

7,5 |

110/115 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

400 |

15,7 |

10 |

110/115 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

500 |

19,7 |

12,5 |

110/115 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

600 |

23,6 |

15 |

110/115 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

700 |

27,6 |

17,5 |

110/115 |

0,2 |

AWG22 |

|

|

50 |

2,0 |

250 |

9,8 |

12,5 |

110/115 |

0,1 |

AWG22 |

|

|

50 |

2,0 |

300 |

11,8 |

15 |

110/115 |

0,1 |

AWG22 |

|

|

50 |

2,0 |

400 |

15,7 |

20 |

110/115 |

0,2 |

AWG22 |

|

|

50 |

2,0 |

500 |

19,7 |

25 |

110/115 |

0,2 |

AWG22 |

|

|

50 |

2,0 |

600 |

23,6 |

30 |

110/115 |

0,3 |

AWG22 |

|

|

50 |

2,0 |

700 |

27,6 |

35 |

110/115 |

0,3 |

AWG22 |

|

|

75 |

3,0 |

400 |

15,7 |

30 |

110/115 |

0,3 |

AWG22 |

|

|

75 |

3,0 |

500 |

19,7 |

37,5 |

110/115 |

0,3 |

AWG22 |

|

|

75 |

3,0 |

600 |

23,6 |

45 |

110/115 |

0,4 |

AWG22 |

|

|

75 |

3,0 |

700 |

27,6 |

52,5 |

110/115 |

0,5 |

AWG22 |

|

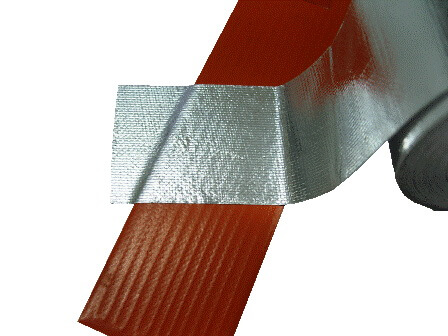

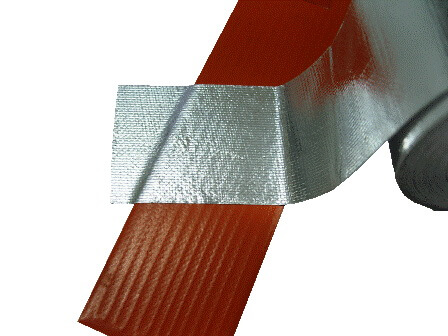

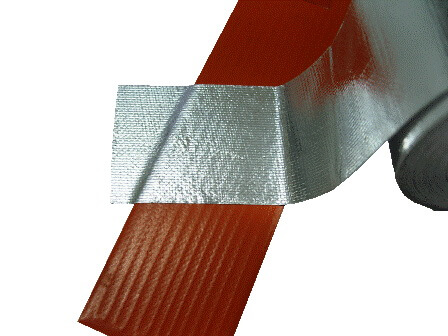

Reinforced high temperature aluminum adhesive tape Reference: 96ALTA0550

Band heater, 0,2w/cm², no controls, 2 wires 200 mm FEP insulated

(Click on reference to download drawing)

|

reference |

Width mm |

Width inches |

Length mm |

Length inches |

Power Watts |

voltage |

amps |

wire size |

|

25 |

1,0 |

250 |

9,8 |

12,5 |

220/230 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

300 |

11,8 |

15 |

220/230 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

400 |

15,7 |

20 |

220/230 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

500 |

19,7 |

25 |

220/230 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

600 |

23,6 |

30 |

220/230 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

700 |

27,6 |

35 |

220/230 |

0,2 |

AWG22 |

|

|

50 |

2,0 |

250 |

9,8 |

25 |

220/230 |

0,1 |

AWG22 |

|

|

50 |

2,0 |

300 |

11,8 |

30 |

220/230 |

0,1 |

AWG22 |

|

|

50 |

2,0 |

400 |

15,7 |

40 |

220/230 |

0,2 |

AWG22 |

|

|

50 |

2,0 |

500 |

19,7 |

50 |

220/230 |

0,2 |

AWG22 |

|

|

50 |

2,0 |

600 |

23,6 |

60 |

220/230 |

0,3 |

AWG22 |

|

|

50 |

2,0 |

700 |

27,6 |

70 |

220/230 |

0,3 |

AWG22 |

|

|

75 |

3,0 |

400 |

15,7 |

60 |

220/230 |

0,3 |

AWG22 |

|

|

75 |

3,0 |

500 |

19,7 |

75 |

220/230 |

0,3 |

AWG22 |

|

|

75 |

3,0 |

600 |

23,6 |

90 |

220/230 |

0,4 |

AWG22 |

|

|

75 |

3,0 |

700 |

27,6 |

105 |

220/230 |

0,5 |

AWG22 |

|

|

25 |

1,0 |

250 |

9,8 |

12,5 |

110/115 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

300 |

11,8 |

15 |

110/115 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

400 |

15,7 |

20 |

110/115 |

0,2 |

AWG22 |

|

|

25 |

1,0 |

500 |

19,7 |

25 |

110/115 |

0,2 |

AWG22 |

|

|

25 |

1,0 |

600 |

23,6 |

30 |

110/115 |

0,3 |

AWG22 |

|

|

25 |

1,0 |

700 |

27,6 |

35 |

110/115 |

0,3 |

AWG22 |

|

|

50 |

2,0 |

250 |

9,8 |

25 |

110/115 |

0,2 |

AWG22 |

|

|

50 |

2,0 |

300 |

11,8 |

30 |

110/115 |

0,3 |

AWG22 |

|

|

50 |

2,0 |

400 |

15,7 |

40 |

110/115 |

0,4 |

AWG22 |

|

|

50 |

2,0 |

500 |

19,7 |

50 |

110/115 |

0,5 |

AWG22 |

|

|

50 |

2,0 |

600 |

23,6 |

60 |

110/115 |

0,5 |

AWG22 |

|

|

50 |

2,0 |

700 |

27,6 |

70 |

110/115 |

0,6 |

AWG22 |

|

|

75 |

3,0 |

400 |

15,7 |

60 |

110/115 |

0,5 |

AWG22 |

|

|

75 |

3,0 |

500 |

19,7 |

75 |

110/115 |

0,7 |

AWG22 |

|

|

75 |

3,0 |

600 |

23,6 |

90 |

110/115 |

0,8 |

AWG22 |

|

|

75 |

3,0 |

700 |

27,6 |

105 |

110/115 |

1,0 |

AWG22 |

Reinforced high temperature aluminum adhesive tape Reference: 96ALTA0550

Band heater, 0,4w/cm², no controls, 2 wires 200 mm FEP insulated

(Click on reference to download drawing)

|

reference |

Width mm |

Width inches |

Length mm |

Length inches |

Power Watts |

voltage |

amps |

wire size |

|

25 |

1,0 |

250 |

9,8 |

25 |

220/230 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

300 |

11,8 |

30 |

220/230 |

0,1 |

AWG22 |

|

|

25 |

1,0 |

400 |

15,7 |

40 |

220/230 |

0,2 |

AWG22 |

|

|

25 |

1,0 |

500 |

19,7 |

50 |

220/230 |

0,2 |

AWG22 |

|

|

25 |

1,0 |

600 |

23,6 |

60 |

220/230 |

0,3 |

AWG22 |

|

|

25 |

1,0 |

700 |

27,6 |

70 |

220/230 |

0,3 |

AWG22 |

|

|

50 |

2,0 |

250 |

9,8 |

50 |

220/230 |

0,2 |

AWG22 |

|

|

50 |

2,0 |

300 |

11,8 |

60 |

220/230 |

0,3 |

AWG22 |

|

|

50 |

2,0 |

400 |

15,7 |

80 |

220/230 |

0,3 |

AWG22 |

|

|

50 |

2,0 |

500 |

19,7 |

100 |

220/230 |

0,4 |

AWG22 |

|

|

50 |

2,0 |

600 |

23,6 |

120 |

220/230 |

0,5 |

AWG22 |

|

|

50 |

2,0 |

700 |

27,6 |

140 |

220/230 |

0,6 |

AWG22 |

|

|

75 |

3,0 |

400 |

15,7 |

120 |

220/230 |

0,5 |

AWG22 |

|

|

75 |

3,0 |

500 |

19,7 |

150 |

220/230 |

0,7 |

AWG22 |

|

|

75 |

3,0 |

600 |

23,6 |

180 |

220/230 |

0,8 |

AWG22 |

|

|

75 |

3,0 |

700 |

27,6 |

210 |

220/230 |

0,9 |

AWG22 |

|

|

25 |

1,0 |

250 |

9,8 |

25 |

110/115 |

0,2 |

AWG22 |

|

|

25 |

1,0 |

300 |

11,8 |

30 |

110/115 |

0,3 |

AWG22 |

|

|

25 |

1,0 |

400 |

15,7 |

40 |

110/115 |

0,4 |

AWG22 |

|

|

25 |

1,0 |

500 |

19,7 |

50 |

110/115 |

0,5 |

AWG22 |

|

|

25 |

1,0 |

600 |

23,6 |

60 |

110/115 |

0,5 |

AWG22 |

|

|

25 |

1,0 |

700 |

27,6 |

70 |

110/115 |

0,6 |

AWG22 |

|

|

50 |

2,0 |

250 |

9,8 |

50 |

110/115 |

0,5 |

AWG22 |

|

|

50 |

2,0 |

300 |

11,8 |

60 |

110/115 |

0,5 |

AWG22 |

|

|

50 |

2,0 |

400 |

15,7 |

80 |

110/115 |

0,7 |

AWG22 |

|

|

50 |

2,0 |

500 |

19,7 |

100 |

110/115 |

0,9 |

AWG22 |

|

|

50 |

2,0 |

600 |

23,6 |

120 |

110/115 |

1,1 |

AWG22 |

|

|

50 |

2,0 |

700 |

27,6 |

140 |

110/115 |

1,3 |

AWG22 |

|

|

75 |

3,0 |

400 |

15,7 |

120 |

110/115 |

1,1 |

AWG22 |

|

|

75 |

3,0 |

500 |

19,7 |

150 |

110/115 |

1,4 |

AWG22 |

|

|

75 |

3,0 |

600 |

23,6 |

180 |

110/115 |

1,6 |

AWG22 |

|

|

75 |

3,0 |

700 |

27,6 |

210 |

110/115 |

1,9 |

AWG22 |

Reinforced high temperature aluminum adhesive tape Reference: 96ALTA0550

Band heater, 0,8w/cm², no controls, 2 wires 200 mm FEP insulated

(Click on reference to download drawing)

|

reference |

Width mm |

Width inches |

Length mm |

Length inches |

Power Watts |

voltage |

amps |

wire size |

|

25 |

1,0 |

250 |

9,8 |

50 |

220/230 |

0,2 |

AWG22 |

|

|

25 |

1,0 |

300 |

11,8 |

60 |

220/230 |

0,3 |

AWG22 |

|

|

25 |

1,0 |

400 |

15,7 |

80 |

220/230 |

0,3 |

AWG22 |

|

|

25 |

1,0 |

500 |

19,7 |

100 |

220/230 |

0,4 |

AWG22 |

|

|

25 |

1,0 |

600 |

23,6 |

120 |

220/230 |

0,5 |

AWG22 |

|

|

25 |

1,0 |

700 |

27,6 |

140 |

220/230 |

0,6 |

AWG22 |

|

|

50 |

2,0 |

250 |

9,8 |

100 |

220/230 |

0,4 |

AWG22 |

|

|

50 |

2,0 |

300 |

11,8 |

120 |

220/230 |

0,5 |

AWG22 |

|

|

50 |

2,0 |

400 |

15,7 |

160 |

220/230 |

0,7 |

AWG22 |

|

|

50 |

2,0 |

500 |

19,7 |

200 |

220/230 |

0,9 |

AWG22 |

|

|

50 |

2,0 |

600 |

23,6 |

240 |

220/230 |

1,0 |

AWG22 |

|

|

50 |

2,0 |

700 |

27,6 |

280 |

220/230 |

1,2 |

AWG22 |

|

|

75 |

3,0 |

400 |

15,7 |

240 |

220/230 |

1,0 |

AWG22 |

|

|

75 |

3,0 |

500 |

19,7 |

300 |

220/230 |

1,3 |

AWG22 |

|

|

75 |

3,0 |

600 |

23,6 |

360 |

220/230 |

1,6 |

AWG22 |

|

|

75 |

3,0 |

700 |

27,6 |

420 |

220/230 |

1,8 |

AWG22 |

|

|

25 |

1,0 |

250 |

9,8 |

50 |

110/115 |

0,5 |

AWG22 |

|

|

25 |

1,0 |

300 |

11,8 |

60 |

110/115 |

0,5 |

AWG22 |

|

|

25 |

1,0 |

400 |

15,7 |

80 |

110/115 |

0,7 |

AWG22 |

|

|

25 |

1,0 |

500 |

19,7 |

100 |

110/115 |

0,9 |

AWG22 |

|

|

25 |

1,0 |

600 |

23,6 |

120 |

110/115 |

1,1 |

AWG22 |

|

|

25 |

1,0 |

700 |

27,6 |

140 |

110/115 |

1,3 |

AWG22 |

|

|

50 |

2,0 |

250 |

9,8 |

100 |

110/115 |

0,9 |

AWG22 |

|

|

50 |

2,0 |

300 |

11,8 |

120 |

110/115 |

1,1 |

AWG22 |

|

|

50 |

2,0 |

400 |

15,7 |

160 |

110/115 |

1,5 |

AWG22 |

|

|

50 |

2,0 |

500 |

19,7 |

200 |

110/115 |

1,8 |

AWG22 |

|

|

50 |

2,0 |

600 |

23,6 |

240 |

110/115 |

2,2 |

AWG22 |

|

|

50 |

2,0 |

700 |

27,6 |

280 |

110/115 |

2,5 |

AWG22 |

|

|

75 |

3,0 |

400 |

15,7 |

240 |

110/115 |

2,2 |

AWG22 |

|

|

75 |

3,0 |

500 |

19,7 |

300 |

110/115 |

2,7 |

AWG22 |

|

|

75 |

3,0 |

600 |

23,6 |

360 |

110/115 |

3,3 |

AWG22 |

|

|

75 |

3,0 |

700 |

27,6 |

420 |

110/115 |

3,8 |

AWG20 |

Adhesive backside: for application on various surfaces such as glass, steel, plastic replace the last character (0) by A

Warning:

- Silicone rubber heaters are not suitable for: radiation, vacuum, or prolonged exposure to

oil

- When these bands are used on thermally insulated pipes, they must be installed under the

insulation and always in contact with the pipe surface. We recommend fixing them on the

equipment with armed adhesive tape (permanent installation) or cable ties (temporary

installation).

Design Services:

Our experienced designers can assist in your design efforts to build a surface heater

specifically for your application. In addition, we can look to optimize your current element

designs and recommend proper watt densities, controls and element construction. We will

conduct a thorough design review and present a proposal and quotation, followed by sample

elements upon approval. We also provide testing services and gather agency approvals to

verify and ensure that the element construction and design will be optimal for your

application.